Materials derived from natural feedstocks, i.e., bio-derived or bio-based materials, can mitigate the dependence on fossil sources and lead to environmental benefits in the applications for which they are designed. In particular, the class of bio-composites has gained the interest of academia and industry in these decades as good mechanical performance can be achieved at a lower environmental impact than traditional composites. Bio-composites often find application as semi-structural components in industrial sectors such as automotive, construction, and packaging.

In this scientific article, the authors (including a participant from a MAGNO partner) focus on two fully bio-based composites, referred to as ‘green composites,’ due to both the matrix and reinforcement phases being derived from renewable sources. Specifically, the matrix consists of poly(lactic acid) (PLA), and the reinforcement is provided by either kenaf fibers or pine needles. The goal of the study is to assess and compare the contributions of the matrix and reinforcement phases in determining the environmental profile of these green composites. This is crucial for thoughtfully selecting materials to realize a truly sustainable solution. The study considered different amounts of fiber content (10–40 vol%) for both kenaf and pine needles in the green composites. In addition to the LCA, the mechanical performance of the two types of green composites is investigated to determine if the benefit could also be functional as well as environmental.

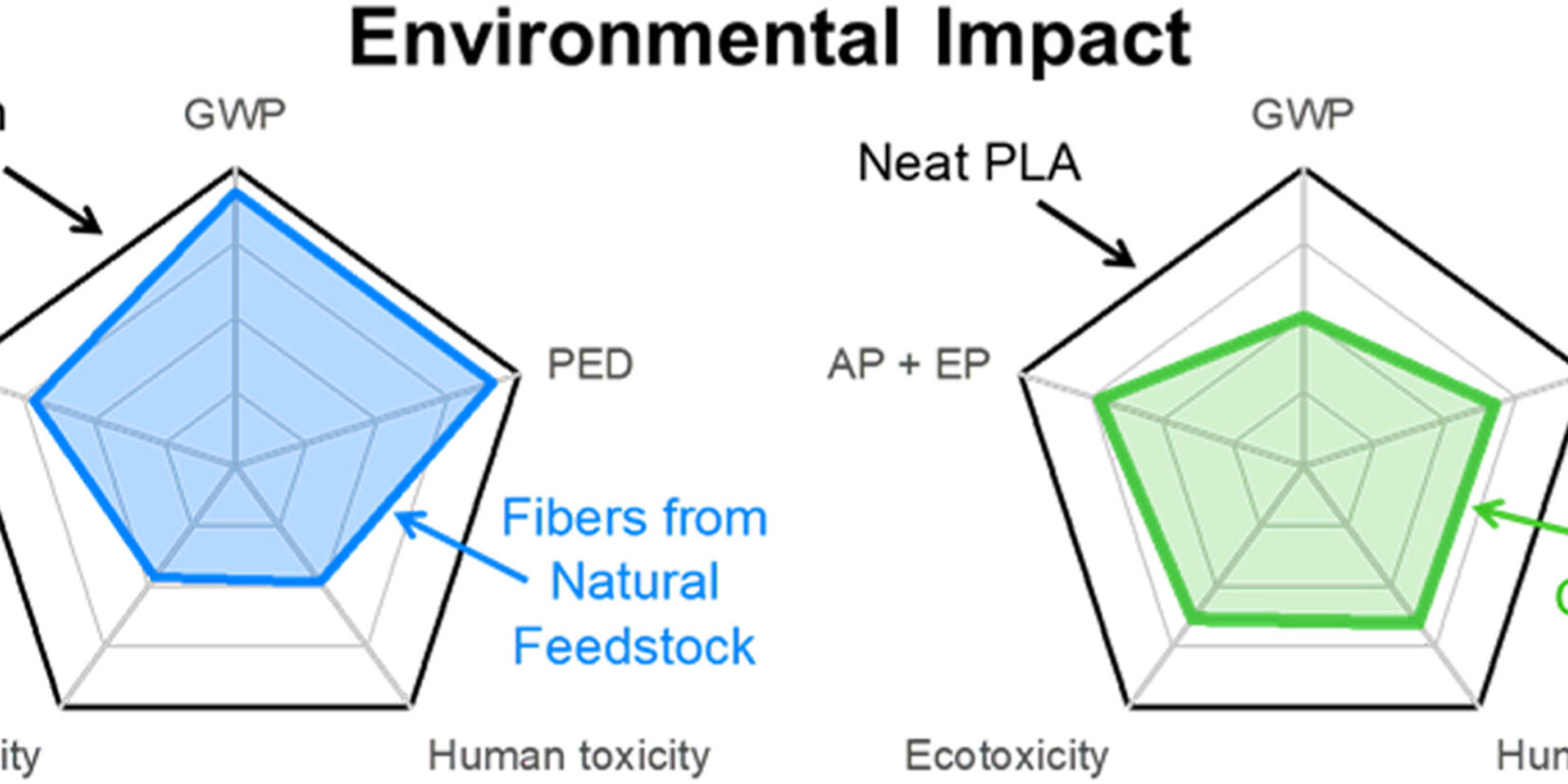

The LCA results show that the PLA matrix is the most impactful phase, nullifying the differences in environmental impact between the fiber types – of which the pine needles have better environmental performance, especially for ecotoxicity indicators. As a general result of the study, the higher the natural fiber content in the green composite, the higher the environmental benefits with respect to neat PLA.

The analysis of the mechanical performance returned that the green composites had an enhanced flexural modulus and eventually ensured the same bending stiffness with reduced weight compared to net PLA. This evidence adds a cost-saving opportunity for potential applications to the observed environmental benefits.

To read the full article, go here: Life cycle assessment of poly(lactic acid)-based green composites filled with pine needles or kenaf fibers – ScienceDirect

Authors: Luigi Operato, Libera Vitiello, Paolo Aprea, Veronica Ambrogi, Martina Salzano de Luna, Giovanni Filippone.

Keywords: green composites; bio-composites; bio-based; PLA; natural feedstock; environmental benefits;